Today is our 2-year anniversary with the Unimog! Huray, party! And although it’s not quite finished, it’s time to reflect on everything we’ve done so far. A list:

- removed the fire-fighter watertank, pump and platform

- removed PTO and it’s extra gearbox

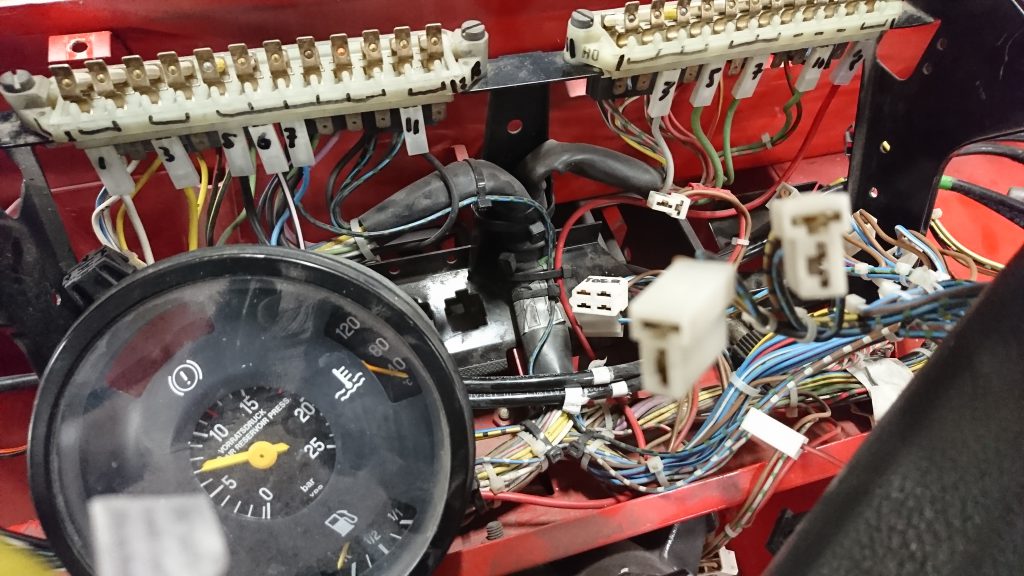

- controlbox, wiring and instruments for flashlights removed

- removed glove compartment, dashboard, heating channels etc en purchased two new heater channels cause the bolt-holes were torn off

- push/pull cable for manual engine control from pump removed

- lifted the cab once to try it out

- repaired right side step, there was a crack in the metal

- removed rear side windows and welded steel plate in place

- repaired rear chassis cross member, a piece was removed there to make room for the pump

- moved the fuel tank from the right to the left side

- fixed a leak in the fuel tank and repainted it

- removed glued floor covering

- created fender supports and rear light supports

- created rear safety bar

- added towing points on chassis rear cross member

- removed the gearbox PTO attachment point and covered it up with, well, a custom cover

- had grill, bumper, steps and winch sandblasted and painted

- prepared install of central door locks

- added an always-on 12 volt cable to the dashboard

- removed door windows and up/down mechanism

- removed doors and windshield

- cleared rust from windshield sill, closed holes and sanded everything

- sanded glove compartment cover, fixed holes and covered with black foil

- sanded dashboard, closed holes and covered with black foil

- installed new exhaust and stainless steel muffler

- modified safety bar at the rear

- sanded body

- tried making sun visor

- moved the master brake cylinder slightly forward and downward

- added a pneumatic quick connector

- designed camper body attachment

- designed camper body with lifting roof

- added rear lights wiring, including pole lights, license plate lighting etc

- found new dashboard indicator lights and switches, designed dashboard for it

- created technical drawings for camper body attachments and had parts laser cut from steel

- put together the camper body attachments, welded it and had it painted

- added a very different hazard light switch

- welded the floor frame for the camper body

- created a wooden pass through frame and tested it by crawling through it, it was large enough for the both of us

- cut a hole in the rear wall of the cab and welded the pass through frame in place

- decided to cut the upper part of the rear wall and replace it, creating a more uniform look for the cab

- got our C1 (truck up to 7500Kg) drivers license

- removed all other items from the cab

- removed the cab from the Unimog, emptied and cleaned it

- started sanding, filling, sanding etc

- removed the metal compartment from the driver-side door

- removed gearbox cover, sanded and painted it

- painted engine cover

- had the cab painted, reinstalled several items

- put our beautiful dove blue cab back onto the Unimog

- added sound-deadening to the floor, body, ceiling, rear wall and doors

- uplifted all grey looking plastic items of the cab so they’re all new black again

- installed bumper, headlights, directional indicators, raised air intake, Mercedes grill star

- exchanged the original 4-wheel and lockers valve with electronical valves

- added floor-covering and sound absorption material to back side, installed door seals

- added wiring for rear view camera

- created new ceiling covers

- cleared break fluid and replaced it

- replaced clutch fluid

- added centrol doorlocking wiring to dashboard and doors

- purchased a passenger seat support

- purchased air-suspension seats

- created adaptors for seat supports

- installed wiring and air for the seats

- installed seats

- reinstalled door windows and up/down mechanism

- added rear-view wiring to dashboard

- installed other cab-parts like stearingwheel, pedals, windshield-wiper motor and others items

- installed plastic door compartments to both doors

- added multi-cable from dash to rear of chassis

- added working lights to rear and switch in the dashboard

- removed the black foil from dashboard and glove compartment and replaced it with grey synthetic leather

- created new ‘door cards’ with the same leather, replaced door grips with second hand washed black ones

- finished reinstalling all parts of the door

- replaced the red door lock sliders with black ones

- finished the new dashboard and installed it

- reinstalled mirros

- glued new rubber seal to hatch

- bolted on the winch and engine cover

- search and found universal window seal, installed a temporary window in the pass through opening

- purchased interior airfilter bracket and installed air filter

- ordered walls for the camper body

- replaced a cover on the passenger seat, it was broken

- created new light-supports for the rear side of the truck

- created side safety items

- measured floormats and made technical drawings for custom floor mats

- installed rear view camera to cab with magnetic holders

All in all, quite the list to be proud of!